Faculty of Engineering, Computing and the Environment

The Faculty of Engineering, Computing and the Environment was formed in 2022. Its schools bring together interdisciplinary research, improving the scope of the student experience and encouraging partnerships between academia and commerce.

Through a collaborative approach, the Faculty offers greater access to resources, knowledge and information and a broader perspective on its subjects, with teaching and research staff working more closely with their colleagues in other disciplines.

Why choose Engineering, Computing and the Environment?

Leaders in research

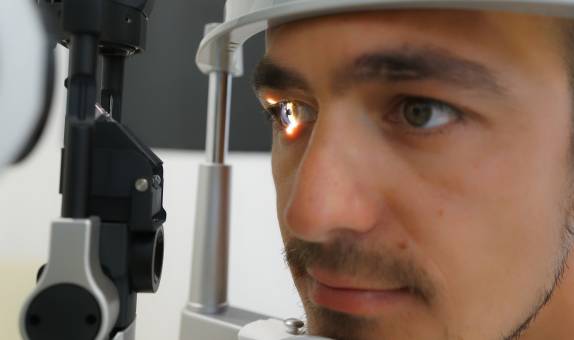

Artificial intelligence-enabled eye scans could be used to rapidly and accurately predict whether a person is at high risk of heart disease, a new study involving researchers from Kingston University has established.

The findings could pave the way for cardiovascular screening to be done more quickly and simply by using cameras, without the need for blood tests or blood pressure measurements.

Circulatory diseases, including cardiovascular disease, coronary heart disease, heart failure and stroke, are major causes of ill health and death worldwide, currently accounting for one in four UK deaths alone. While several risk frameworks exist, these aren't always able to accurately identify those who will go on to develop or die of circulatory diseases.

As part of the study, Kingston University Professor of Computer Vision Sarah Barman and postdoctoral researcher Roshan Welikala developed artificial intelligence (AI) algorithms that could reliably measure features on the retinal image, such as the width of blood vessels and how curved they were.

Read the full paper in the British Journal of Opthalmology.

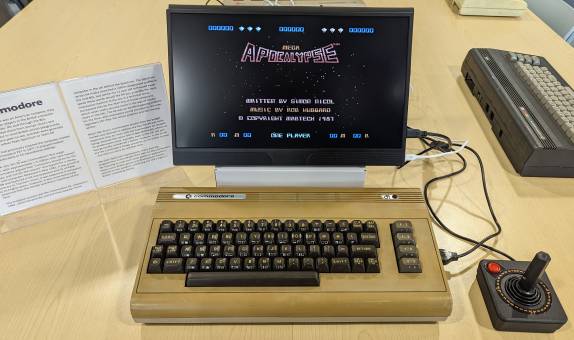

World-class facilities

We offer our students the opportunity to learn and grow in a real-world environment. Combined with our hands-on approach to teaching and learning, this provides our students with the skills ready for their chosen industry.

These skills are taught within our world-class facilities, providing our students with some of the most innovative and advanced technology in order to have the freedom to invent, create and revolutionise their practice.

See each course page for the facilities you might use, below are some of our most cutting-edge facilities.

Flight simulator

Our aircraft engineering students have access to our flight simulator. It is equipped with visual display, instrumentation, pilot controls, motion base and instruction station.

CAVE

Our computer science and gaming students have full access to the University's CAVE (Centre for Augmented and Virtual Reality Environments), a treasure trove of specialist equipment.

Kingston, London

Kingston University is based in Kingston upon Thames, a busy riverside town on the borders of London and Surrey, with central London just 30 minutes away by train.